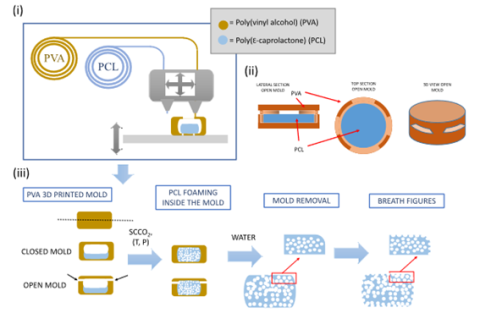

Biocompatible three-dimensional porous scaffolds are widely used in multiple biomedical applications. However, the fabrication of tailor-made 3D structures with controlled and combined multiscale macroscopic-microscopic, surface and inner porosities in a straightforward manner is still a current challenge. Herein, we use multimaterial fused deposition modeling (FDM) to generate poly (vinyl alcohol) (PVA) sacrificial moulds filled with poly (Ɛ-caprolactone) (PCL) to generate well defined PCL 3D objects. Further on, the supercritical CO2 (SCCO2) technique, as well as the breath figures mechanism (BFs), were additionally employed to fabricate specific porous structures at the core and surfaces of the 3D PCL object, respectively. The biocompatibility of the resulting multiporous 3D structures was tested in vitro and in vivo, and the versatility of the approach was assessed by generating a vertebra model fully tunable at multiple pore size levels. In sum, the combinatorial strategy to generate porous scaffolds offers unique possibilities to fabricate intricate structures by combining the advantages of additive manufacturing (AM), which provides flexibility and versatility to generate large sized 3D structures, with advantages of the SCCO2 and BFs techniques, which allow to finely tune the macro and micro porosity at material surface and material core levels.

20/07/2023

Polycaprolactone with multiscale porosity and patterned surface topography prepared using sacrificial 3D printed moulds: Towards tailor-made scaffolds

Title: Polycaprolactone with multiscale porosity and patterned surface topography prepared using sacrificial 3D printed moulds: Towards tailor-made scaffolds

Journal: Biomaterials Advances, 2023. DOI: 10.1016/j.bioadv.2023.213465